The index system on the stock Legacy Ornamental Mill is a nice start if you ask my opinion. The stock index plate comes with 24 holes. From this you can index 2,3,4,6,8,12 and 24 locations. The flexibility is great. Legacy also sells a 5 piece index plate set that includes 28, 30, 32, 36, and 40 positions. There is also an "Expanded Indexing System" that includes 16,72,80,96,120 locations. This chart shows the details.

Plates |

Possible Index Locations | Degree |

No. of Indexes |

|---|---|---|---|

| Stock | |||

| 24 | 1,2,3,4,6,8,12,24 | 15.0º |

8 |

| .25 Reduction | |||

| 48 | 1 , 2 , 3 , 4 , 6 , 8 , 12 , 16 , 24 , 48 | 7.5 |

10 |

| 5 Plate Set | |||

| 28 | 1,2,4,7,14,28 | 12.85º |

6 |

| 32 | 1,2,4,8,16,32 | 11.5º |

6 |

| 36 | 1,2,3,4,6,9,12,18,36 | 10.0º |

9 |

| 40 | 1,2,4,5,8,10,20,40 | 9.0º |

8 |

| Expanded Set | |||

| 16 | 1,2,4,8,16 | 22.5º |

5 |

| 72 | 1,2,3,4,6,8,9,12,18,24,36,72 | 5.0º |

12 |

| 80 | 1,2,4,5,8,10,16,20,40,80 | 4.5º |

10 |

| 96 | 1,2,3,4,6,8,12,16,24,32,48,96 | 3.75º |

12 |

| 120 | 1,2,3,4,5,6,8,10,12,15,20,24,30,40,60,120 | 16 |

|

Summary |

|||

| All Indexes | 1-10, 12, 14-16, 18, 20, 24, 28, 30, 32, 36, 40, 48, 60, 72, 80, 96 | 27 |

|

| Missing Indexes | 11, 13, 17,19, 21-23, 25-27, 29, 31, 33-35, 37-39, 41-47, 49-59, 61-71, 73-79, 81-95, 97-119 | 93 |

The complication comes when you have a short attention span and you loose track of your count. This happened to me one too many times, and I started to go down the path of making indexing error proof.

The second component of the indexing is the looseness in the stock components. The cutting force of a 2" core box router bit can be very extreme. Even a 1/2" core box cutter can cause the index system to fail and make a wavy cut. In my stock machine, the spindle will rotate up to 1.5 degrees when making a cut. I will address some of these issues and discuss possible solutions.

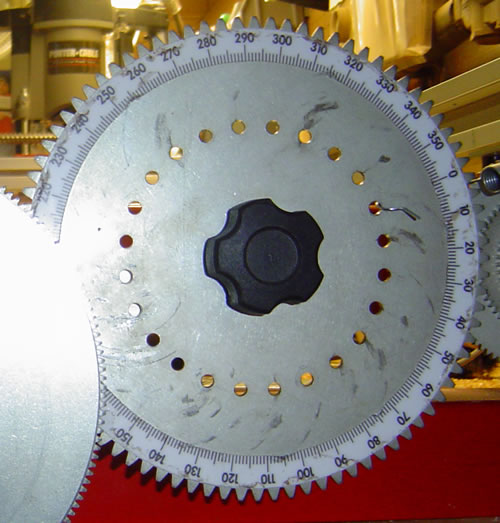

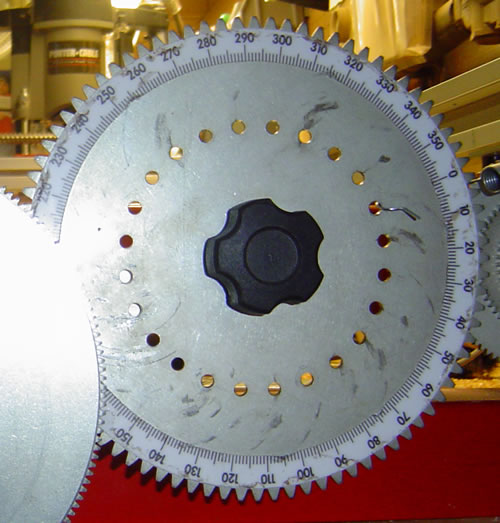

I started by first adding a degree wheel to my stock index plate. This helped me see what angle I was at when the index pin was in a hole. Then I found that I had to think about what degree the cut should be at. I could have simply made a cheat sheet that showed the angles required for the number of indexes that you were working. Instead, I decided to take it another step, and eliminate memory and math from the indexing operation.

For those wanting a simple angle chart, you can use this one with my permission.

Index |

Angle |

Sequence |

|---|---|---|

2 |

180 |

0, 180 |

3 |

120 |

0, 120, 240 |

4 |

90 |

0, 90, 180, 270 |

6 |

60 |

0, 60, 120, 180, 240, 300 |

8 |

45 |

0, 45, 90, 135, 180, 225, 270, 315 |

12 |

30 |

0, 30, 60, 90, 120, 150, 180, 210, 240, 270, 300, 330 |

24 |

15 |

0, 15, 30, 45, 60, 75, 90, 105, 120, 135, 150,165, 180, 195, 210, 225, 240, 255, 270, 285, 300, 315, 330, 345 |

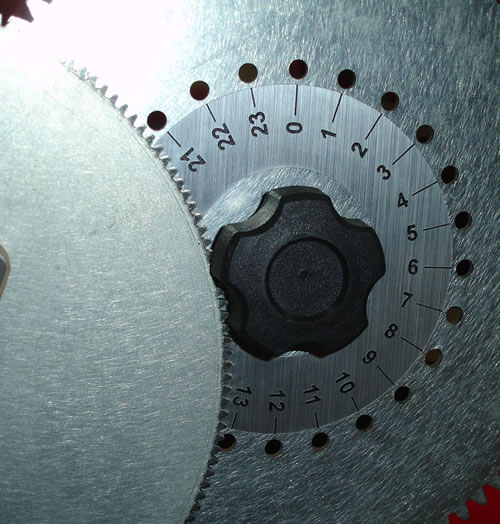

The next step in eliminating error was to make block off plates that fit in between the headstock and the index plate. They are made from 1/4" HPDE. The design is simple, a notch is provided for each index that you need. The other holes are blocked out. A pin prevents the template from rotating. This really increased the speed of indexing. I could no longer stick the index pin in the wrong hole.

This is what the block off plate for 12 locations looks like. I made block off plate for each combination that the stock index plate is capable of. I also made a few templates for a non standard pattern that I frequently use. These were all cut on a cnc machine.

These block off plates were a great step for making indexing error proof, but I decided to take it one more step, and eliminate any hassle.

The next step in making indexing goof proof was to replace the stock Legacy index gear with my own custom index plates using a cnc guided laser to accurately index and machine the holes. I made a set of index plates from steel for 5,6,7,8,9,10, 12 and 14 places. Now I could simply mount a plate with the correct number of holes for the small work that I do.

If I were to make larger work, I would make more index wheels with more holes. I have a plan to make index plates that include a mechanism to double the index very easily. I will save that idea for the future.

I would love to show you what these plates look like, But I lost the pictures in my last hard drive crash. I will take some photos soon.

Ok, maybe a little bit of math could make indexing easier but using a degree wheel and adding big numbers to figure out the indexes was a challenge. I believe this latest method is the fastest and most reliable method for indexing.

I have invented a new method of indexing on the Legacy Ornamental Mill by creating a new index wheel label that makes indexing more reliable and easier to use. The number scheme allows you to verify your results before making an index cut.

To use this numbering system you simply decide the number of indexes that you would like. Then, divide that number into 24 and that determines the increment number. Then use the increment number to determine your locations on the label.

Here's an example, let's say you wanted three indexes. You divide 24 by 3 and the answer is 8. That is your increment number. Using your times tables you know that the sequence for the index cuts would be 0, 8, 16. This is extremely easy to align the pin to the correct number on the index wheel.

The only possible equally spaced divisions on the stock 24 hole index plate are 1,2,3,4,6,8,12,24. Here's the simplified sequence chart.

Index |

Angle |

Sequence |

|---|---|---|

1 |

0 |

0 |

2 |

180 |

0, 12 |

3 |

120 |

0, 8, 16 |

4 |

90 |

0, 6, 12, 18 |

6 |

60 |

0, 4, 8, 12, 16, 20 |

8 |

45 |

0, 3, 6, 9, 12, 15, 18, 21 |

12 |

30 |

0, 2, 4, 6, 8, 10, 12, 14, 16, 18, 20, 22 |

24 |

15 |

0 , 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22, 23 |

Now with the counting issues smoothed out, I started noticing flex problems. The spindle would twist and rotate when cutting. This happens in cuts that are parallel with the spindle, and perpendicular to the spindle. This turns into crooked coves, less than perfect polygon shapes, and broken lines that do not wrap around your piece.

The first thing that I noticed is the slight amount of space in the index gear itself. The rectangle hole in the index plate is slightly oversized and twists on the spindle end. To eliminate that, I installed a bolt and washer in the place of the plastic knob provided by legacy. I am now able to put more torque on the bolt using a wrench instead of my hand. This helped, but then I noticed that the stock MT drive started to rotate in the spindle.

To solve that problem, I invested in Legacy's double locking collar. Now that I own that accessory, I have to admit that it belongs on the must have list of accessories. Buy one today if you plan on using the stock drive mount.

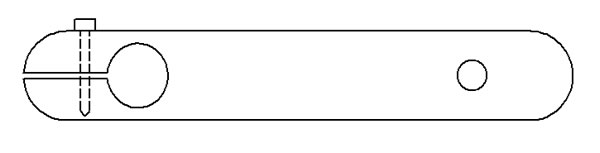

Now I started to notice that the spindle was still capable of twisting. I decided to build a spindle lock. The idea was to take a bar of aluminum and bore a hole to slide over the spindle. The other end of the bar has a hole that slips over the index pin on the headstock. The hole for the spindle has a slice and a screw that pulls the slice together to pinch the spindle to prevent any movement.

It would look like this:

I made a prototype of this arrangement, and it mostly worked. I made it from plastic, and it slipped. I have other ideas for a spindle lock that I will share when completed. If you make the spindle lock, please let me know how well it works for you. Call it a TK Spindle lock in my honor.

In the mean time rather than waiting for me to make a spindle lock that works, Mike Pung showed the Google Legacy group his solution. A vise grip and a block of wood to hold the index gear to the pivot arm linkage. This eliminates the pin bending and moving in the bore. Simple is good sometimes!

Is this the end of the story? Not likely. I have been working on an adjustable index system. It is still a few months away. I also have another solution for the moving index plate. More to come...

The double locking collar enables a trick that is under utilized, and not really documented. Did you know you can cut 48 equal places using your 24 hole index plate?

Start by cutting your 24 index cuts in your piece. Now, loosen the double lock collar and rotate the work 7.5 degrees and cut your next 24 indexes. You now have 48 indexed cuts. The 7.5 degrees is the index angle divided by two. By changing the degree you rotate your piece, you can index any multiple of numbers you choose. You just need imagination and a clever way to know the angle adjustment. If you need hints, let me know. I may add them here.

Mike Pung had another idea to solve the indexing problem. He called it, "Crank Handle Indexing". Read More about this method.

I have made a really simple web based tool that will help you determine all of the possible index locations given the number of holes on the index plate, or teeth on a gear. Simply enter the number of holes or teeth and click the button to see the results.

I also made a chart of index plates from 3-360 holes and all of the possible indexes available.

Please do not distribute the links to my software tools.

If you would like to purchase a degree wheel sticker, custom machined plastic templates or laser cut index plates with any hole combination, please feel free to contact me.

Disclaimer: I am not associated with Legacy Woodworking or Phantom Engineering.

If you have any question or comments, please feel free to email me. Tim

Web Page updated 9-1-10 All rights reserved.